Space

60 years of successful service to the space odyssey

A driver of continuous progress, the space industry is currently undergoing a renaissance; a profound transformation into a more competitive environment as it enters the commercial era. Private companies can understand the wonderful challenges and rewards that space provides, so they are among the primary contributors to this dynamic. They are focusing on the production of telecommunications data (internet, GPS, etc.), terrestrial imaging (digital agriculture, smart cities, smart energy, etc.), climate observation, and the prevention of natural risks.

Air Liquide is ready to meet the challenges of this new chapter in the history of space. After more than 60 years of technological developments on the Ariane, Melfi, Planck, Herschel, Curiosity, and ExoMars programmes, we have the ambition, the will and the expertise to engage in all the major new international challenges: sustainable space exploration, electric propulsion, more competitive launch vehicles, constellation of satellites, life in space, and more.

770+

tanks for Ariane program

Air Liquide supports you throughout the different phases of your project, from design to operation, carrying out studies and analysis, in order to optimize the dry mass of launcher stages, maximize the embarked propellant and reduce the thermal inputs. We contribute to your trade-offs, using methodologies that combine advice, solution design and cost control, with an innovative approach.

From propellant production to engine feeding onboard your launcher: Air Liquide can supply a complete solution: engineering of the fluidic supply systems, propellants, operations and maintenance, etc.

Air Liquide has more than 40 years of experience in space launch pads infrastructures, with onsite services and operation at Kourou in French Guiana (for Europe) and gas supply for Cap Canaveral (US) and Tanegashima (Japan).

Our solutions

Thanks to our expertise in very low temperatures, we provide customized solutions to produce, manage and distribute cold to meet a wide range of requirements in the field of satellites: observing the thermal radiation of the universe, cooling the infrared sensors on earth observation satellites or preserving biological samples taken on the International Space Station (ISS)...

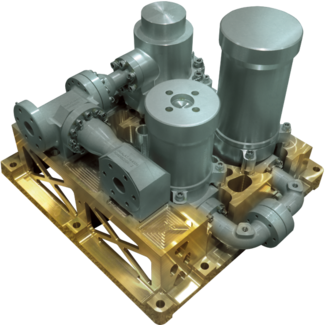

When using xenon as a fuel, the satellites’ weight can be cut by two. Air Liquide’s teams have developed a global solution for electric propulsion satellites, including flow control system, xenon supply and filling service. We can also provide gas management devices, supply and services related to other gases such as krypton, helium, etc.

Our solutions

Based on our expertise, we would like to contribute to developing a sustainable space exploration by adapting our terrestrial technologies (i.e energy transition technologies) for the lunar ambition. We are especially focusing on gas purification, fuel cells, liquefaction, high performance cryogenic storage, fluid filling stations, ...

As an industrial company, we consider that gases and cryogenics will be a cornerstone of a sustainable human presence in space, and useful for the development of transverse European service capabilities that all nations will need.

Air Liquide’s RFCS Regenerative Fuel Cell System is a technology combining a fuel cell, an electrolyzer and tanks of water, oxygen and hydrogen. This system uses the solar energy during the day to convert water into oxygen and hydrogen thanks to electrolysis. During the nights, this oxygen and hydrogen are used to produce electricity, thermal energy and water via a fuel cell. The regenerative fuel cell thus works in a closed circuit.

Leveraging our experience and expertise in gas purification for terrestrial markets (health, heavy industry, energy transition), Air Liquide is developing prototypes to purify oxygen (O2) and water (H2O) from the Moon. When these molecules are extracted, they will be mixed with other molecules and will need to be purified to meet the purity level required by new use cases (oxygen for astronauts to breathe in the air cabins, water for astronauts or electrolyzers, ….). In addition, Air Liquide is also testing new technologies to improve current systems used to trap CO2 exhausted by astronauts. This will be key for the settlement of humans on the Moon.

The development of lunar activities, in particular In-Situ Resource Utilization (ISRU), will lead to mass production of oxygen and probably hydrogen (if finding and extracting icy water is successful). Therefore the storage and supply of these molecules will be key to unlock use cases (such as refueling of spacecraft, life support, energy, etc.). Based on its expertise in extreme cryogenics through the Ariane program, but also with terrestrial products to reliquefy methane boil-off, Air Liquide will develop a system capable of liquefying H2 and O2 and deliver it to customers. The system will be compatible with the lunar environment (extreme temperatures and low gravity) and another system compatible with Earth and moon orbits (no gravity).