The use of cryogenic propellants for launch vehicles requires thermal insulation of the tanks, lines, and equipment to protect them from their environment.

This equipment contains propellants at temperatures ranging from– 193°C to – 253°C, while the outside temperature on the launch pads reaches 30°C, and the walls of the launch vehicle heat up to 180°C when they go through the atmosphere.

Key figures

|

- 193 à – 253°C |

Propellant temperatures |

|

180°C |

Temperature of the outer panels when they cross the atmosphere |

|

4 |

different types of insulation |

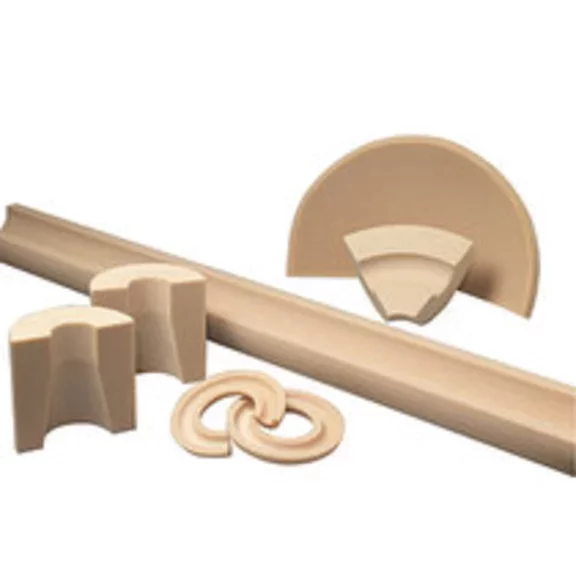

Ultra-lightweight materials with low thermal conductivity

- Closed cell material, used for the external insulation of Ariane's main cryogenic tanks and distribution lines thanks to its low density ǀ Density: 45 kg/m3 before thermoforming, thermal conductivity: 33 mW/m.K at room temperatureXXX, maximum temperature: 90°C in continuous use, 450°C in transient use

- DacronTM felt, covered with an aluminum liner to insulate the Ariane launch vehicle's internal cavities ǀ Density: 6 kg/m3

- Multi-layer insulation, used to protect the LHESS ǀ ~0.25 W/m² between 4 K and 300 K, for 40 layers of MLI (Multi-Layer Insulation)

- Vacuum honeycomb bulkhead ǀ Thickness: 20 mm, high static and dynamic structural strength with excellent insulation properties, 100 W/m2 between 22 and 190 K

A few key benefits

- Proven experience ǀ This isolation has been used on successive generations of Ariane launch vehicles

- Bespoke services ǀ We can design and adapt insulation that is perfectly suited to your specific requirements, in particular the thermoforming and preparation of the insulation on demand and in accordance with quality standards for space applications.

- Suitable for a variety of applications ǀ The diversity of solutions means it is suitable for a wide variety of applications

- An on-site test zone ǀ A test zone for conducting mechanical and thermal tests on the insulation in a cryogenic environment

Solid references

- The entire European launch vehicle program, Ariane

Contact Us

For more information, find on this page your key contacts and our contact form.

Space

Air Liquide has the ambition, the will and the expertise to engage in all the major new international challenges: electric propulsion, more competitive launch vehicles, the constellation of satellites, life in space, and more.