Air Liquide’s Turbo-Brayton technology confirms its success with more than 130 units sold

- Marine

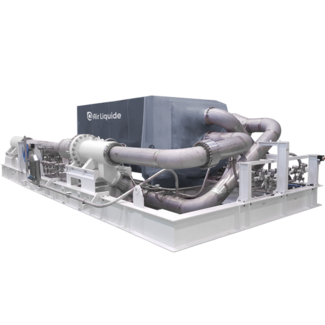

Air Liquide achieved a new milestone with its Turbo-Brayton cryogenic equipment, with more than 130 units sold since the launch of the product, in 2016. This innovative solution serves both the maritime transport and the clean mobility industries.

The technology, developed by Air Liquide and based on the Turbo-Brayton principle, is mainly used to reliquefy LNG (Liquefied Natural Gas) boil-off on vessels transporting that product, thereby reducing greenhouse gas emissions during transportation. This equipment is designed to be installed on LNG carriers and bunker vessels, both on newly built ships and to retrofit existing vessels.

This Air Liquide technology was first used in the space industry to cryogenically preserve biological samples on the International Space Station (ISS), before being adapted for the maritime transport industry. It is also used to liquefy biomethane generated through the anaerobic digestion of household and agricultural waste. In liquid form, the biomethane can be transported easily to its point of use, as a fuel in NGV stations (Natural Gas for Vehicles) or in ferry terminals.