Air Liquide presents the latest developments to its Turbo-Brayton cryogenic technology to the Go LNG project

- Marine

On May 9, Air Liquide presented its extended range of Turbo-Brayton cryogenic refrigerators and liquefiers to the Go LNG project during a study visit to its liquefaction plant in Lidköping in Sweden. The Go LNG project, which is working to develop an LNG infrastructure in the Baltic sea region, brings together representatives of ports, shipowners, cities, universities, and the LNG/LBG sector.

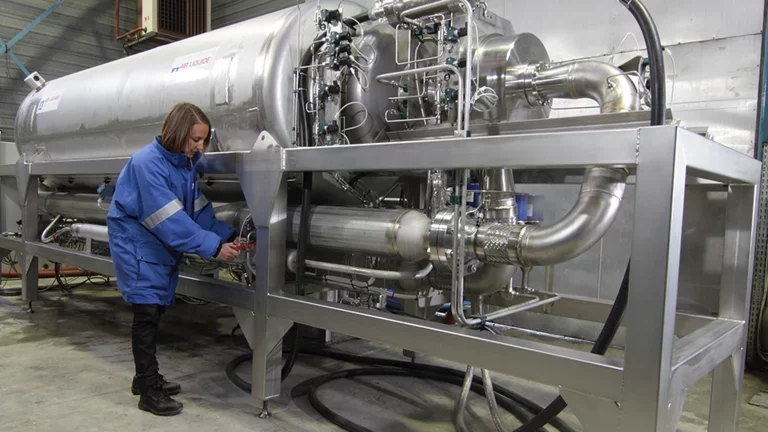

Air Liquide's Turbo-Brayton technology has many advantages for the burgeoning market for liquid natural gas for ship transportation (logistics, bunkering stations, etc.): compared to equipment that uses Brayton cycle technology, Turbo-Brayton improves the reliability and efficiency of refrigeration and liquefaction processes and reduces installation and operating costs related to the systems' electrical consumption and maintenance operations.

Air Liquide recently extended its Turbo-Brayton range to include off-shore solutions that enable the reliquefaction of boil-off gas (BOG) on ships of various sizes (bunkering ships, LNG carriers, ships powered by natural gas, etc.). In 2016, Air Liquide won two contracts to supply Turbo-Brayton systems; with GasLog LNG Services for the equipment of two LNG carriers (model TBF-1050), and with Shell for its first bunker vessel (TBF-350 ).