Turbo-Brayton for BOG reliquefaction on LNG terminals

An ideal solution for boil-off reliquefaction on small LNG terminals (<500,000 m3)

The easy-to-install skid-mounted product is suitable for all types of containment technology. As a BOG reliquefaction system, Turbo-Brayton is efficient and extremely reliable, with cooling power available instantly from standby mode and a low power consumption. The maintenance interval is 5 years.

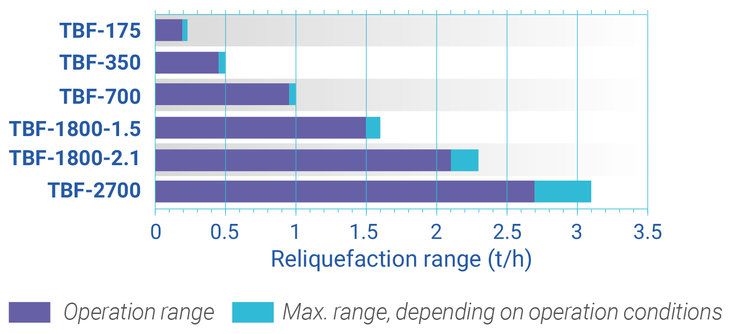

The Turbo-Brayton range offers reliquefaction capacities from 0.2 ton/h to 3 ton/h, with additional range possible by duplicating the modules. This boil-off reliquefaction system can be installed on new constructions or during a retrofit operation.

Turbo-Brayton range

Key benefits

- Single-skid solution: Easy installation, plug-and-play design, quick start, small footprint

- Simple integration thanks to sub-cooling

- Safety with inert and non-flammable gas, leak tight

- High reliability: with contactless and oil-free technology - MTBF (Mean Time Between Failures) of 105,000 h

- No additional operating costs: no compressed air, no oil, no nitrogen or additional refrigerant gas

- Vibration free

- Significantly reduced preventive maintenance: just a few days every 5 years

- Fully automatic operation without human intervention

- Operation possible between 0% and 100% and high efficiency over the entire operating range

- Operational flexibility: unlimited number of starts and stops, no waiting time between starts and stops

References

With more than 230 Turbo-Brayton systems sold, Air Liquide is a world leader in BOG reliquefaction offshore.

Onshore, the Turbo-Brayton equips the Higas LNG terminal in Sardinia to manage the BOG

Contact Us

For more information, find on this page your key contacts and our contact form.

Marine

Air Liquide manufactures gas production, storage, and regeneration systems for submarines and surface vessels and works on pioneering projects using our expertise in hydrogen and nitrogen.