Turbo-Brayton as Subcooler - BOG reliquefaction offshore

Turbo-Brayton cryogenic systems for the reliquefaction of Boil-Off Gas

It is a fast and easy-to-install skid-mounted product, that is suited to both atmospheric and pressurized storage. With cooling power available instantaneously from stand-by mode to full capacity and low electrical consumption, Turbo-Brayton technology is extremely reliable. Its maintenance interval is 5 years.

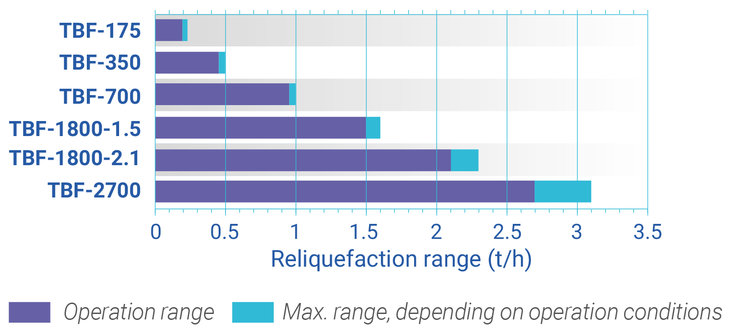

The Turbo-Brayton range has reliquefaction capacities varying from 0.2 t/h to 3 t/h, and more by duplicating modules. This boil-off reliquefication system can be installed on both new constructions and retrofitted vessels.

A Boil-off reliquefaction solution that is suited to a wide range of vessels

- Bunker vessels and bunker barges (from 1,000 to 30,000 m3)

- LNG-powered vessels

- LNG carriers (from 15,000 to 250,000 m3)

- Multigas carriers

- FSRU and FSU

Off-shore Turbo-Brayton range

Key benefits

- Single skid solution: Easy installation, Plug and play design, Short start-up, Low footprint

- Easy integration thanks to subcooling

- Safety with inert and non flammable gas, leak tight

- High reliability: with contact free, oil free technology -MTBF = 105,000 h

- Utility free: no compress air, no oil, no nitrogen or any refrigerant gas make-up

- Vibration free

- Drastically reduced maintenance = few days each 5-years

- Fully automatic, unmanned operation

- Turndown possible between 0% and 100% and high efficiency on all operation range

- Flexibility in operation: unlimited number of starts and stops, no waiting time between starts and stops

References

With more than 160 Turbo-Brayton units sold, Air Liquide is a world leader in offshore BOG reliquefaction.

Our solution has been mentioned in the media:

For LNG Carrier (more than 130 references)

Video introducing range of TBF (video 45 sec)

TBF-1225 first commissioning (June 2020)

TBF-1225 first commissioning (June 2020)

TBF-1050 successful commissioning (April 2018)

TBF for marine sector (Feb 2020)

TBF-1225 on Edison Elisa Aquila (Feb 2022)

For Bunker Vessels (more than 30 references)

TBF-350 on Cardissa (video 45 sec)

TBF-350 on QLNG-4000 (video 1min 45s)

TBF-700 on Gas Agility (Dec 2020)

TBF-350 on US LNGBV (Dec 2020)

TBF-350 on Coral Methane (June 2020)

TBF-700 on Gas Agility (June 2020)

TBF-700 installed as retrofit on LNG Bunker Vessel (July 2022)

For FSRU/FSU/LNG Terminal

2xTBF-1225 on BW FSRU (March 2021)

For Onshore subcooler

Subcooling principle

About subcooling (video 4min 38sec)

Turbo-Brayton for LNG bunker vessel

Contact Us

For more information, find on this page your key contacts and our contact form.

Marine

Air Liquide manufactures gas production, storage, and regeneration systems for submarines and surface vessels and works on pioneering projects using our expertise in hydrogen and nitrogen.