World Leader in High Technologies for the Gas Field.

Find your solution

Meet our teams!

4 results

About us

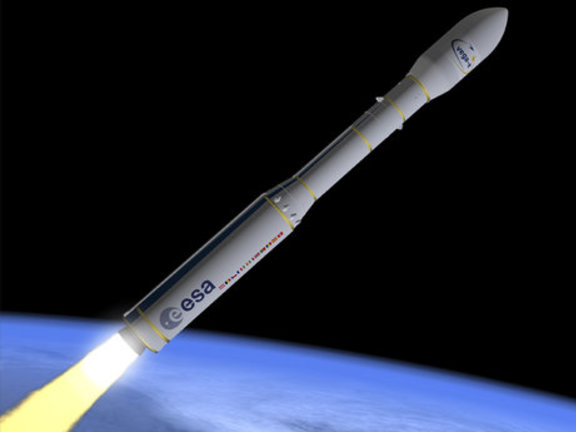

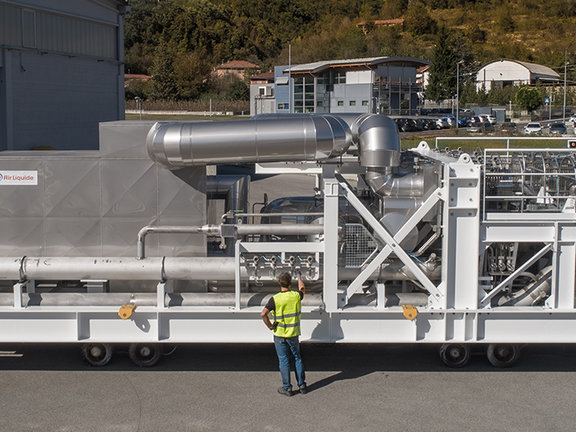

World leader in high technologies in the field of gas, Air Liquide advanced Technologies puts its expertise to work for numerous sectors: space, science, industry and marine.

Contact us

If you have a question about any of our equipment, services or resources, please feel free to call or send us a message.